The Role of Plastic Injection Molding in Creating Affordable Industrial Parts

The Role of Plastic Injection Molding in Creating Affordable Industrial Parts

Blog Article

Checking Out the Applications of Plastic Injection Molding Across Industries

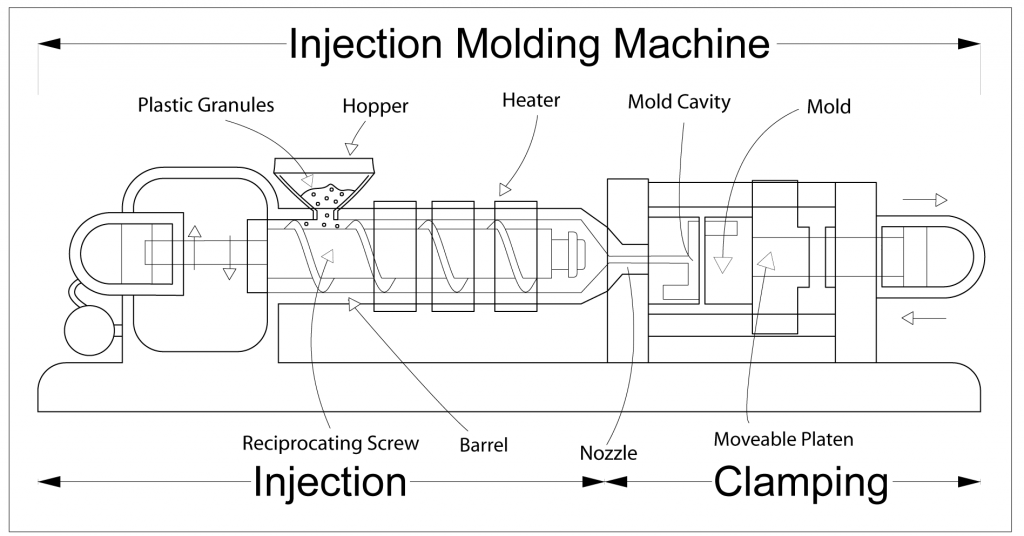

Plastic shot molding stands as a foundation of modern-day production, using remarkable flexibility across varied markets such as vehicle, consumer products, healthcare, and electronic devices. Its capacity to produce detailed, lightweight parts effectively has not only enhanced product efficiency however has also added to cost-effectiveness. As sectors significantly prioritize sustainability, the integration of cutting-edge materials provides both challenges and opportunities. Recognizing exactly how these developments affect the landscape of production can expose much about future fads and methods (Plastic Injection Molding). What implications do these growths hold for markets progressing?

Automotive Market Innovations

Changing the automobile landscape, plastic injection molding has become an essential modern technology in the manufacturing of innovative automobile parts. This manufacturing process permits the creation of lightweight parts and complex geometries, substantially adding to automobile performance and performance.

In contemporary automotive style, plastic injection molding promotes the manufacturing of components such as bumpers, dashboards, and interior trim pieces. These elements not just boost visual allure yet additionally boost safety and performance. For example, the ability to mold intricate styles allows the assimilation of advanced functions like air bag systems and digital user interfaces directly into the structural components.

As the automobile sector remains to embrace independent and electric innovations, the duty of plastic shot molding will certainly become significantly vital. Its versatility and performance setting it as a keystone technology for future advancements in vehicle design and manufacturing, driving advancements toward a much more lasting automobile ecosystem.

Consumer Product Production

The influence of plastic injection molding prolongs past the auto industry, substantially affecting customer goods producing. This flexible strategy makes it possible for the manufacturing of a wide array of products, ranging from home products to complex digital components. The ability to create complex shapes and designs with high accuracy enables suppliers to fulfill customer needs for both performance and aesthetics.

One of the primary advantages of plastic shot molding in durable goods is its effectiveness. The process enables for high-volume production, decreasing manufacturing prices and preparation. This performance is crucial in a market characterized by swiftly transforming consumer preferences and fads.

Ultimately, plastic injection molding works as a keystone in consumer items producing, enabling the development of varied, premium items that deal with evolving market demands while making best use of functional performance. This adaptability ensures its continued significance in the competitive landscape of consumer items.

Healthcare Applications

In the healthcare industry, plastic injection molding plays a crucial function in the manufacturing of a large range of clinical tools and components. This production strategy makes it possible for the production of complex and accurate forms required for different applications, from surgical instruments to diagnostic devices.

Additionally, plastic shot molding permits the combination of features such as texturing and complicated geometries, which can improve the functionality and individual experience of clinical devices. The procedure additionally sustains fast prototyping and short preparations, enabling makers to react rapidly to market requirements and technical developments.

Electronic Devices Production Techniques

As markets significantly depend on advanced manufacturing processes, plastic injection molding has actually also found considerable applications within electronics manufacturing. This method enables the efficient development of complex parts that are important for contemporary electronic gadgets. From smart device coverings to circuit boards, the precision and versatility of injection molding facilitate the production of premium components that meet rigorous sector requirements.

One of the important benefits of plastic injection molding in electronics is its capacity to generate intricate geometries that would certainly be testing to attain with standard manufacturing methods. The rapid cycle times associated with click to find out more the process additionally improve production efficiency, permitting manufacturers to respond promptly to market demands.

In addition, the usage of specialized thermoplastics can improve the efficiency of electronic elements. Products such as polycarbonate and ABS supply high sturdiness and outstanding electric insulation, making them excellent for applications varying from adapters to housing enclosures.

In addition, injection molding supports the assimilation of numerous functions into single parts, decreasing assembly time and prices. As innovation continues to advancement, the role of plastic injection molding in electronics production is likely to expand, driving innovation and improving product efficiency across the market.

Sustainability in Injection Molding

Sustainably including techniques in injection molding significantly shapes the future of production, dealing with expanding environmental worries. As industries make every effort for eco-friendliness, the injection molding process adapts by applying energy-efficient investigate this site technologies and lasting materials. Recycled and naturally degradable plastics are obtaining traction, minimizing dependence on fossil fuels and decreasing waste.

Additionally, innovations in machinery and techniques goal to reduced power intake during production. For circumstances, electrical shot molding devices are coming to be more common, using substantial reductions in energy usage contrasted to typical hydraulic systems. These devices not just save power yet additionally boost accuracy and lower cycle times, leading to lower functional costs.

Moreover, companies are adopting closed-loop systems to take care of waste successfully. By reusing scrap product produced throughout the manufacturing procedure, they can lessen environmental impact and advertise source efficiency (Plastic Injection Molding). Executing sustainable practices in injection molding not just fulfills governing needs but additionally deals with the boosting customer demand for environmentally responsible products

Verdict

In conclusion, plastic shot molding offers as an important production procedure across different sectors, including auto, consumer products, healthcare, and electronic devices. Thus, plastic injection molding stays essential for satisfying the vibrant needs of contemporary markets while advertising sustainable manufacturing techniques.

Plastic injection molding stands as a foundation of modern-day production, providing exceptional convenience throughout varied sectors such as vehicle, customer items, healthcare, and electronics.In modern vehicle layout, plastic shot molding helps with the production of elements such as bumpers, control panels, and indoor trim pieces.As industries progressively depend on sophisticated production procedures, plastic shot molding has actually also found significant here applications within electronics production.In conclusion, plastic injection molding serves as an important manufacturing process across various industries, including automobile, consumer goods, healthcare, and electronics. Thus, plastic injection molding remains essential for meeting the dynamic needs of modern-day markets while advertising lasting production techniques.

Report this page